CA Sports Legendary Bat Makers

Posted by IB Sports on Feb 5th 2021

We carry all of CA manufactured bats as they design and manufacture world class English willow bats, there are number of reasons that they make superior bats. In order to understand why their bats are legendar we need to understand little bit of history:

When did CA Sports came into existence:

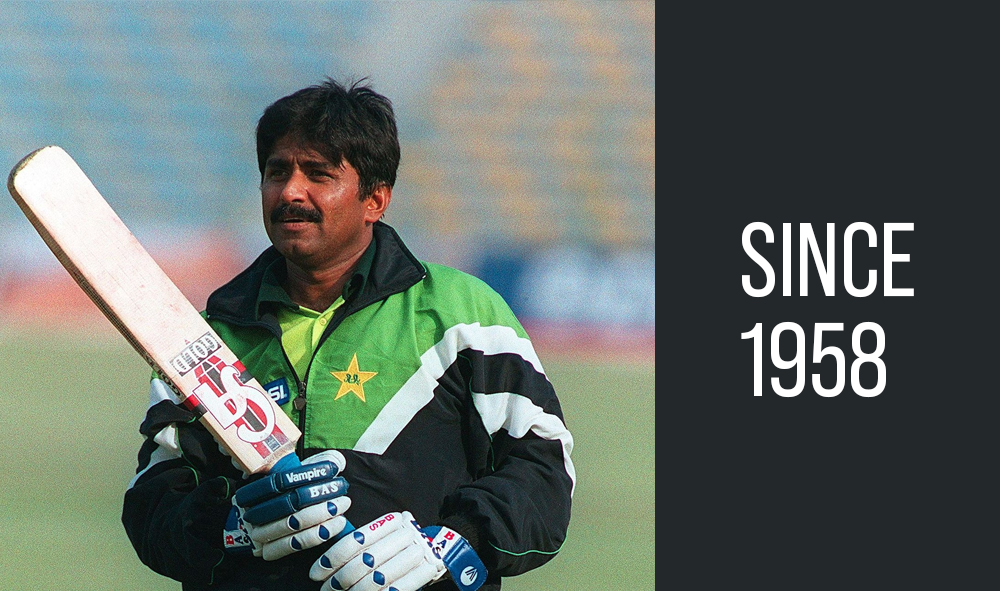

CA owns a strong history of providing quality sports equipment since the time it was founded by Charaghdin Abdulrasheed in Sialkot. CA Sports started with manufacturing wooden tennis rackets and started production of cricket bats and sponsored their first cricketer, Salim Malik in 1978.

CA is trying to get recognition in the international market. Brand Ambassadors of CA Sports are Tamim Iqbal from Bangladesh, Tillakaratne Dilshan from Sri Lanka, Shoaib Malik from Pakistan, Chris Gayle from West Indies. CA has sponsored many national & international players like Inzamam ul Haq, Javed Miandad, Saeed Anwar, Moin Khan, Saleem Malik, Ijaz Ahmed, Umer Akmal, Haris Sohail, Misbah-ul-Haq, Younis Khan, Brian Lara, Carl Hooper, Michael Bevan, Tillakaratne Dilshan, Mahela Jayawardene, Marvan Atapattu, Jacob Oram, Shakib Al Hasan, and Shoaib Malik. CA is the official supplier to the Pakistan Cricket Board and sponsors the national cricket team

CA produces 40,000 to 45,000 regular bats every year and up to 500,000 tape ball bats. “CA is the pioneer in tape ball bats.” The bats are only sold in Pakistan and Bangladesh and the wood used for these bats comes from Mansehra, Peshawar, Abbottabad, and Rawalkot

Lets go through some of their legendary cricket bats design techniques and inovations

CURVED SHAPE Bat

The curve-shaped bats we see in today’s cricket were first produced by CA in 1979.

Why their bats are lighter even with such a thick blade

This question gets asked a lot, CA is the only manufacture in Pakistan that uses special wood drying process to dry English Willow to manage its moisture content to such a level that perfect willow comes out of it which is super light with immense hitting power. If you notice the ping and shot noise of their bats is very sharp like its hard wood but in reality, it feels soft in playing.

Why is CA putting Factory knocked-in ready

In south east Asia most Cricket Bat manufactures run a process called wood pressing. This helps in hardening the wood fiber that is why CA bats may only need 2-3 hours of hand knocking-in with little amount of Linseed oil for wood protection. Refer our Bat care section to understand detail process.

What is the benefit of more corks/plastic layer in handle

Superior bats have 4 - 5 layers of corks, now a day’s handle makers also started using plastic with cork inserted at top layer. Multiple layers help bat absorbs shock you may feel when bat hit ball hard. More layers mean more shock absorption.

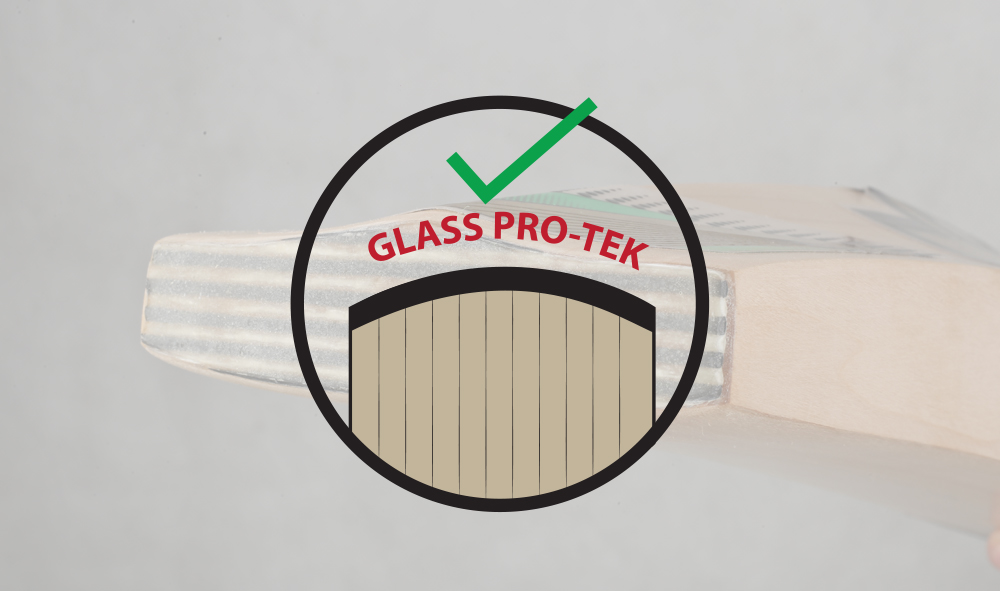

What is this new toe protection from CA called Glass PR-TEK

Glass Pro-Tek is a new protection guard on the toes of CA cricket bats. A balanced formulated semi-see-through material fitted at the toes of cricket bats for protection and durability of cricket bats. Quite advance than the existing rubber toe protection, it protects the bat for a longer time and refrains from chipping and damage.

Since our cricket bats are played within a variety of pitches like hard soil, concrete, the taping of the bat can reduce its age and destroy its aesthetics especially at the lower end. Playing on wet ground can pump moisture into the willow of the bat which consequently becomes an agent in damage and cracks. But with the Glass-Pro-Tek technology one has not to worry about his/ her cricket bat's health anymore.